Table of Contents

Soft robotics is a fast-growing field that has a wide array of applications that range from space exploration to prosthetics. So, a Yale University research team took the tech a step further and invented a smart, robotic fabric that has the ability to change its shape and softness on demand.

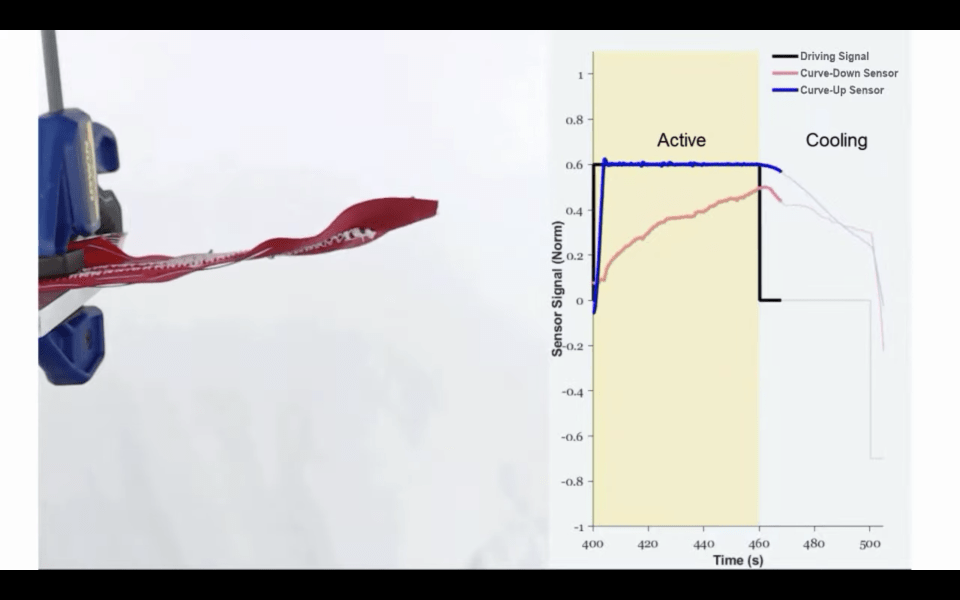

The fibers themselves are what actually giving this material this capability Dr. Rebecca Kramer-Bottiglio and her team managed to spin epoxy into fibers that can change their level of stiffness due to their Field’s alloy embedded in them. Field’s metal liquefies at very low temperatures, making it rather unique. When it’s cool, it remains solid and the smart robotic fabric is stiff. When a low current is applied, however, the Field’s metal becomes malleable. This happens to the entire piece of fabric.

This Smart Robotic Fabric is as Flexible as Rubber, as Stiff as Acrylic

Trevor Buckner, the studies lead author said, ‘Our Field’s metal-epoxy composite can become as flexible as latex rubber or as stiff as hard acrylic, over 1,000 times more rigid, just by heating it up or cooling it down. Long fibers of this material can be sewn onto a fabric to give it a supportive skeleton that we can turn on and off.’

Also, the research team was able to develop a liquid sensor that can detect changes in the material. The sensor can detect the temperature of whoever is wearing the smart robotic fabric. It can also detect the temperature of the environment. The fabric can literally have this sensor painted onto it. The team also embedded shape-memory wires into the fabric. They can bend themselves into pre-programmed shapes. Electric current exposure is the trigger.

The Air Force Office of Science Research is funding this research. The government organization plans to use this new high-tech fabric in things like smart cargo netting. They also plan on using it for smart tourniquets.

If you liked this article, you might like this one about Tesla’s car.